Nov16

Innovation in 3D: Ice Dream #DSCC11

Point: Test large-scale innovations for 1/20th the cost by using 3D simulations to prove viability and performance.

Point: Test large-scale innovations for 1/20th the cost by using 3D simulations to prove viability and performance.

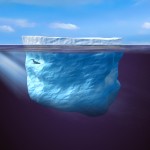

Story: Forty years ago, Georges Mougin got an idea: solve water shortages in drought-ridden countries by towing an iceberg over the sea to them. Floating icebergs are pure drinking water, but they slowly melt into seawater. Why not harvest them before all that drinking water is lost?

The idea of towing an iceberg, however, seemed crazy. When Mougin talked with scientists about the idea, objections abounded. “Once you get north of the equator, you’ll have nothing but a rope at the end of your tow,” said Wilford Weeks of the U.S. Army Cold Regions Research and Engineering Laboratory at a conference in 1977 when hearing of the idea. Other questions were: how much power would it take to tow 100-million ton iceberg? What would be the environmental impact of it melting in equatorial waters once it was anchored at a coastal city?

Although Mougin was confident of the idea’s viability, he had no way to prove it. Despite securing the backing of a Saudi prince, Prince Mohammed al Faisal, the projected costs and unanswered questions proved insurmountable. But Mougin continued working on the idea, doggedly amassing data on issues like ocean currents and learning how technologies from other industries, like those developed for off-shore oil drilling, could be tapped.

Mougin’s lucky break came in 2009, when he heard of Dassault Systemes‘ “Passion for Innovation” program. Dassault Systemes sponsors the Passion for Innovation program as a philanthropic venture to give individuals or nonprofits free access to Dassault Systemes’ suite of products (CATIA, DELMIA, SIMULIA, ENOVIA, 3DVIA. SoildWorks, Exalead) as well as a team of Dassault Systemes engineers.

“We’ll help you and provide you with the modeling and simulation technologies that should demonstrate that your project is feasible,” said Cedric Simard, IceDream Project Director, Dassault Systemes.

Dassault Systemes worked with Mougin: “We used virtual and digital simulation technology to recreate a virtual world around the iceberg, taking into account real oceanographic and weather data to simulate the sea currents at several depth levels, as well as the wind, waves, and even the impact of the sun’s rays,” Simard said.

After using CATIA software to create an exact model of the iceberg, the team used Dymola for the complex simulation, factoring in issues like ocean temperatures that would affect melting en route as well as meteorological phenomena like wind. The team also used SIMULIA software to consider risks such as fracturing of the iceberg. Running these simulations enabled the team to test the concept for a fraction of the cost of building a prototype: $500,000 instead of $10 million.

The simulations proved that it’d be possible to tow a 7-million-ton berg with one tugboat, primarily relying on ocean currents and consuming only 4000 tons of fuel over the 140-day journey, Simard said. The berg would experience some melting (38%) but still provide enough drinking water for 20,000 people for one year.

“Mougin is a very passionate guy,” Simard said. “He’s 87 years old, and he’s been working on his project for forty years. Now thanks to the power of simulation and the digital world, he can see how his idea would work in reality.”

Action:

- Create mathematical models of large-scale innovations

- Ground the model in real-world conditions and environments with empirical data

- Estimate performance, costs, potential failure modes using advanced software

- Present a compelling graphical story of the innovation with 3D visualization.

Sources and Additional Information:

My video interview with Cedric Simard on CollaborativeInnovation.org

“Dassault Puts Inventor’s ‘Ice Dream’ to 3D Simulation Test” by Beth Stackpole

“Iceberg Transport” by Lauren K. Wolf

Comments Off on Innovation in 3D: Ice Dream #DSCC11Case study, Entrepreneurs, interview, R&D, Software tool, Uncategorized