Mar04

Additive Manufacturing Multiplies Innovation Opportunities

Point: Additive manufacturing (also called 3D printing) technologies enable new design methods and local manufacturing by entrepreneurs.

Story: When designing a new part to be manufactured, designers traditionally had to define the shape they wanted and then pick the material that could support that shape (based on strength, flexibility, etc.). That is, they designed the piece separate from picking the materials. For more complex products, designers had to decompose the product into semi-independent parts that were designed and manufactured separately and then assembled with screws, welding, clips, glue, and so on. This deconstructive process risked incompatibilities between the parts, added complexity, and increased costs due to a assembly labor.

But, nature does not design in this deconstructive way. A tree trunk, limbs and leaves aren’t built separately and assembled. Rather, nature designs and grows the entire tree in a progressive, additive fashion, and largely from one material. Nature starts with a material (e.g., cellulose is the material for trees) and deploys that material in various densities, shapes, thicknesses, and modified formulations to create an integrated object. The same basic building-block material that makes the thick rigid truck of a tree also makes the broad, flat leaves of the tree, thin flexible twigs, and hard shells of the tree’s nuts.

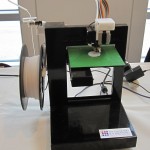

Additive manufacturing mimics nature (unlike traditional reductive manufacturing that removes material to make a form). Additive manufacturing can build almost any shape that can be drawn on a computer, including hollow and contorted forms impossible to make in other ways. Specialized machines (essentially 3D printers) lay down layer after layer of material or draw with a bead of molten material to grow the part the 3D shape that was downloaded from the computer. Virtually anything that someone can imagine, draw or compute in 3D can be made with additive manufacturing.

Several competing 3D printer technologies let designers and manufacturers choose between clear resins, colored opaque thermoplastics, powered metals, and even powered ceramics. Companies can use the technology to create prototypes, customized shapes, spare parts, and intricate parts in low quantities. For example, Boeing used metal hybrid additive manufacturing processes and powdered metal manufacturing to create parts that reduced the weight and fuel consumption of its aircraft.

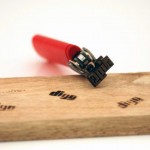

Although industrial printers like Boeing’s cost upwards of $500,000, consumer-grade printers cost only $1300. The low price point creates a vast new opportunity for entrepreneurs to provide 3D printing services. For example, online service company Shapeways prints any design that its customers upload, from fashion and jewelry pieces to gadgets and art. Even better, Shapeways lets is members open virtual storefronts on the site to sell their products. Some of the most popular products for sale include a PirateBay ship model, a Dymaxion world map, and a customized metal branding iron that will brand any text you want when attached to a BIC lighter. In addition, open source communities (such as MakerBot Industries, RepRap, Thingiverse) are dedicated to creating ultra-low cost printers and sharing designs for cool additive manufactured parts.

Action

- Think about how in-house 3D printing (or in-home 3-D printing) might change your business.

- Design new additive manufactured products based on shapes that would be “impossible to build” with traditional manufacturing.

- Create new business models based on products or services that support additive manufacturing or that transcend the curse of economies of scale needed by traditional manufacturing

2 Comments »Entrepreneurs, Growth, Innovation, New Product Development, Opportunity, Strategy